- HOME

- Technology

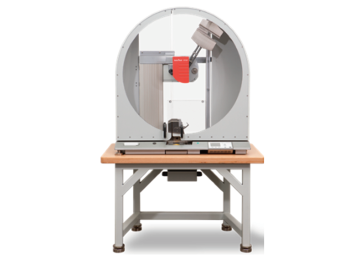

- Pandulum Impact Tester

Pandulum Impact Tester

Specification

| Item | Zwick HIP25P Plus |

|---|---|

| Max impact energy | 25J |

| Charpy pendulum | l,4,7.5J |

| Dimensions (W×H×D) | 1180× 1170×500 mm |

| Weight | 215 kg |

| Impact velocity | 2.9 m/s up to 3.8 m/s |

| Test temperature | Room temp. |

| Test standard | ISO 179 ASTM 06110 |

Test standard including possible applications

| Standard requirements | HIT 5P | HIT 5.5P | HIT 25P | HIT 50P | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Method | Standard | Pendulum energy J |

ft lbf | Velocity at impact m/s |

Stand alone | PC | Stand alone | PC | Stand alone | PC | Stand alone | PC |

| Chparpy | ISO 179 | 0.5 | 0.37 | 2.9m/s (±10%) | ● | ● | ● | ● | ● | ● | ● | ● |

| 1 | 0.74 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 2 | 1.48 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 4 | 2.95 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 5 | 3.69 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 7.5 | 5.53 | 3.8m/s (±10%) | - | - | - | - | ● | ● | ● | ● | ||

| 15 | 11.1 | - | - | - | - | ● | ● | ● | ● | |||

| 25 | 18.4 | - | - | - | - | ● | ● | ● | ● | |||

| 50 | 36.9 | - | - | - | - | - | - | ● | ● | |||

| ASTM D6110 | 0.5 | 0.37 | approx 3.46m/s | - | - | ● | ● | ● | ● | ● | ● | |

| 1 | 0.74 | - | - | ● | ● | ● | ● | ● | ● | |||

| 2.7 | 2 | - | - | ● | ● | ● | ● | ● | ● | |||

| 5.4 | 4 | - | - | ● | ● | ● | ● | ● | ● | |||

| 10.8 | 8 | (Height of fall: 610±2mm) | - | - | - | - | ● | ● | ● | ● | ||

| 21.6 | 16 | - | - | - | - | ● | ● | ● | ● | |||

| lzod and “Un notched cantilever beam impact” | ISO 180 | 1.0 | 0.74 | 3.5m/s (±10%) | - | - | ● | ● | ● | ● | ● | ● |

| 2.75 | 2.03 | - | - | ● | ● | ● | ● | ● | ● | |||

| 5.5 | 4.06 | - | - | ● | ● | ● | ● | ● | ● | |||

| 11 | 8.11 | - | - | - | - | ● | ● | ● | ● | |||

| 22 | 16.2 | - | - | - | - | ● | ● | ● | ● | |||

| ASTM D256/ D 4812 | 1.0 | 0.74 | approx 3.46m/s | - | - | ● | ● | ● | ● | ● | ● | |

| 2.75 | 2.03 | - | - | ● | ● | ● | ● | ● | ● | |||

| 5.5 | 4.06 | - | - | ● | ● | ● | ● | ● | ● | |||

| 11 | 8.11 | (Height of fall: 610±2mm) | - | - | - | - | ● | ● | ● | ● | ||

| 22 | 16.2 | - | - | - | - | ● | ● | ● | ● | |||

| Tensile impact | ISO 8256- method A | 2.0 | 1.48 | 2.9m/s (±10%) | ● | ● | ● | ● | ● | ● | ● | ● |

| 4.0 | 2.95 | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 7.5 | 5.53 | 3.8m/s (±10%) | - | - | - | - | ● | ● | ● | ● | ||

| 15.0 | 11.1 | - | - | - | - | ● | ● | ● | ● | |||

| 25.0 | 18.4 | - | - | - | - | ● | ● | ● | ● | |||

| 50.0 | 36.9 | - | - | - | - | - | - | ● | ● | |||

| Tensile impact- “tensile-in-head” method | ISO 8256- method B | 2.0 | 1.48 | 2.9m/s (±10%) | - | - | ● | ● | ● | ● | ● | ● |

| 4.0 | 2.95 | - | - | ● | ● | ● | ● | ● | ● | |||

| 7.5 | 5.53 | 3.8m/s (±10%) | - | - | - | - | ● | ● | ● | ● | ||

| 15.0 | 11.1 | - | - | - | - | ● | ● | ● | ● | |||

| 25.0 | 18.4 | - | - | - | - | ● | ● | ● | ● | |||

| 50.0 | 36.9 | - | - | - | - | - | - | ● | ● | |||

| ASTM D1822 | 2.7 | 2 | approx 3.46m/s(Height of fall: 610±2mm) | - | - | ● | ● | ● | ● | ● | ● | |

| 5.4 | 4 | - | - | ● | ● | ● | ● | ● | ● | |||

| 10.8 | 8 | - | - | - | - | ● | ● | ● | ● | |||

| 21.6 | 16 | - | - | - | - | ● | ● | ● | ● | |||

| Dynstat | DIN 53435 | 0.2 | 0.15 | 2.2±0.1m/s | - | - | - | - | - | - | - | - |

| 0.5 | 0.37 | - | - | ● | ● | ● | ● | ● | ● | |||

| 1.0 | 0.74 | - | - | ● | ● | ● | ● | ● | ● | |||

| 2.0 | 1.48 | - | - | ● | ● | ● | ● | ● | ● | |||

| 4.0 | 2.96 | - | - | ● | ● | ● | ● | ● | ● | |||